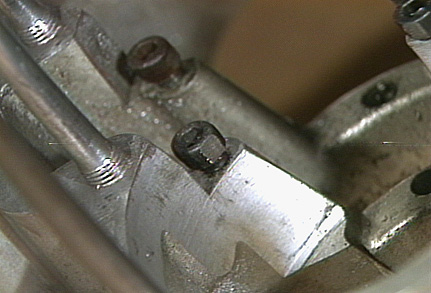

Boring the case: you install thecam chain tensioner bracket

(shoe upside down) with speciallyprovided allen screws,

but the boring bar will still nipthem a bit, also the inner

diameter of the bracket. Clampwell, go slow for this.

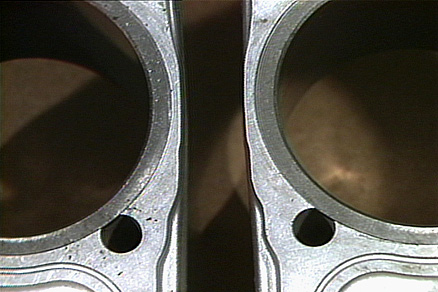

840 liners installed. Halco kithas special two-piece dowels to get around the interference.

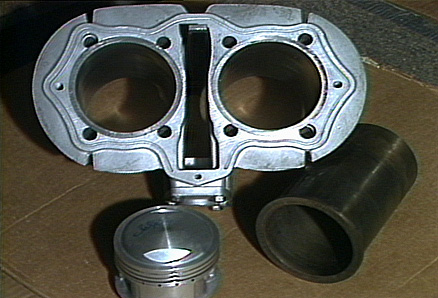

Larger lungs:

completed cylinder and 840 pistonvs. stock liner.

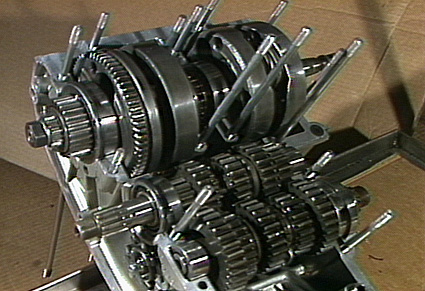

277 crank in place, Carrillo rods.These or European 552 rods required.

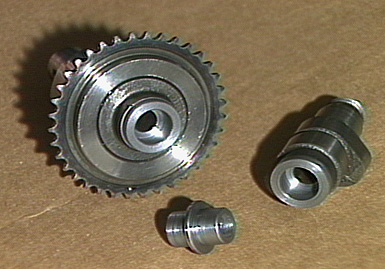

If you'd rather not pay the priceto have the lobes re-positioned professionally, here's

an alternative. Stock D cam wasparted, larger I.D.s turned into ends, button made to exactly

replace removed metal. Retainsaxial alignment when re-indexing. With the whole shaft

and button held together by a longbolt (engine stud and washers, head nuts work great),

you can locate the offset indexesexactly. Grind into the button flange, burn in a good bead

across all three pieces, rotate180, repeat, rotate 90, repeat, rotate 180, repeat, etc. This way

you don't warp the axial alignmentwith welding heat.

Recommend indexing the offset marks

in the engine with the same setupyou would use to degree-in the cam. I've done this twice

and found slight differences inthe amount of offset from one engine to the next, possibly

due to any number of variablesinvolving crank wheels, cam chain or sprockets, actual

cam grind, wear, or just plainpilot error. Best to take the time, do the work of set-up with

the actual parts you will be using,be accurate, double-check before welding.

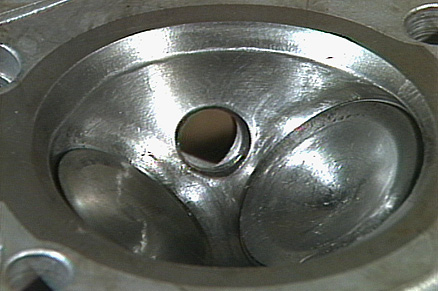

Removal of ridges around valvepockets is recommended by vintage racers to improve flow.

Ports are opened to 38mm, polished.R&D valve springs keep 'em honest.

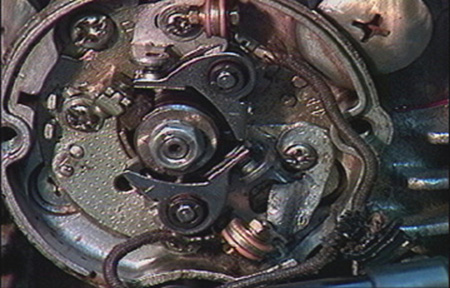

Lower point set can be moved withouttoo much improvising:

Can be done in either direction

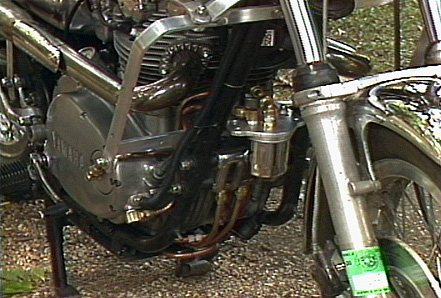

Cooling the beast:

Oil flow is tapped out from theprimary case, fed to Summit thermostat, which bypasses

the cooler until temp reaches 180;this unit also eliminates air traps in system. Oil returns through

10 micron spin-on filter. Cooleris 10 feet of 3/8 copper tubing coiled into one-inch space below

crankcase, shielded by stainlessfloor plate. Relocated exhaust mounts make perfect

brackets for this, plate also scoopsair, may help stiffen frame. Because bulk of extra oil is

stored/circulated below, nominalcrankcase level is not much affected.

Extra guage is for oil pressurepeace-of-mind. Likewise for small unit above turn signal

indicator lights: (it's a Dynaunit that monitors charging system status.)

Extra lever under clutch is compressionrelease.

Monster Thanks to:

Bob Bertaut of Sports, Inc.

Mike Lalonde of Mike's XS

Ted Cole of Cole Tool, Inc.

Tony Hall and Halco, U.K.

Dave Rayner Down Under

Mike 'Mercury' Morse of VintageBrake

XS 650 Society Intl.

Summit Racing

E Mail Info Request.............AboutEarthcom

Residential BuildingTrades.....The Fifty-Minute House

Pricing

Film Festival Documentaries:

The Last Real Circus..................Mr. Jefferson's Rotunda

Patrick Henry,Virginia Patriot

Patrick Henry'sFight for Individual Rights

The Brews Brothers

Copyright 2002 Earth Communications Corporation